Note: Please purchase this adapter board to use it with Arduino and Raspberry Pi.

Store Pickup Available!

Store Pickup Available!

Free Ship Over 5000 BDT

Free Ship Over 5000 BDT

Quality Product

Quality Product

No Warranty

No Warranty

No Replacement

No Replacement

The PMS5003 is a low-cost laser particle counter, one of a range of sensors by Plantower that also include the PMS1003, PMS3003, and PMS7003. PMS5003 is a kind of digital and universal particle concentration sensor, which can be used to obtain the number of suspended particles in the air, i.e. the concentration of particles, and output them in the form of a digital interface. This sensor can be inserted into variable instruments related to the concentration of suspended particles in the air or other environmental improvement equipment to provide correct concentration data in time. RoboticsBD

Air Quality Sensor that can measure particulate matter like PM2.5, PM1.0, PM10.

Plantower PMS5003 is a laser dust sensor. Sensor uses laser light scattering principle to measure value of dust particles suspended in the air. Sensor provides precise and reliable reading of PM2.5 value. If you are looking for PM2.5 and PM10 please look at Nova Fitness SDS011. RoboticsBD

WITNESS real-time, reliable measurement of PM2.5 dust concentrations! (PM2.5 refers to particles that are 2.5 microns or smaller in diameter.) This sensor uses laser scattering to radiate suspending particles in the air, then collects scattering light to obtain the curve of scattering light change with time. The microprocessor calculates equivalent particle diameter and the number of particles with different diameter per unit volume. RoboticsBD

Breathe easy, knowing that you can track and sense the quality of the air around you with the PM2.5 Air Quality Sensor with Breadboard Adapter particulate sensor. Mad Max & Furiosa definitely should have hooked up one of these in their truck while scavenging the dusty desert wilderness of post-apocalyptic Australia. And for those of us not living in an Outback dystopia, this sensor + adapter kit is great for monitoring air quality, and super easy to use! Featured By RoboticsBD.

Product Images are shown for illustrative purposes only and may differ from the actual product.

RoboticsBD RoboticsBD RoboticsBD RoboticsBD RoboticsBD RoboticsBD RoboticsBD RoboticsBD RoboticsBD RoboticsBD

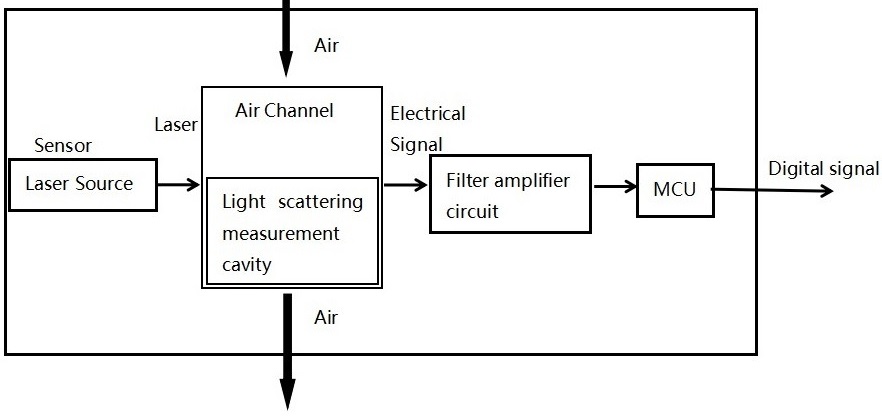

How does this Sensor work?

Well, This sensor works on the principle of laser scattering, which entails irradiating suspended particles in the air with a laser to cause scattering, collecting the scattered light at a specific angle, and calculating the intensity of the scattered light over time. Furthermore, the microprocessor calculates the equivalent particle size of the particles and the number of particles of various particle sizes per unit volume using the MIE theory algorithm.

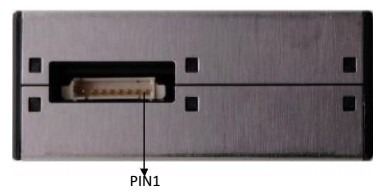

Some of the PM2.5 pins are numbered from left to right as 1, 2, 3……8. But in case of PM5003, the pins are named from right to left. Be careful while connecting PM5003 pins as you might connect it reversely.

RoboticsBD RoboticsBD RoboticsBD RoboticsBD RoboticsBD RoboticsBD RoboticsBD RoboticsBD RoboticsBD RoboticsBD

| General Specification | |

| Supply voltage: | 4.5 V to 5.5 V// Logic-3.3V |

| Power consumption (work): | below 100 mA |

| Power consumption (standby): | below 200 μ |

| Sensitivity | 50% - 0.3 μm 98% - 0.5 μm and larger |

| Resolution: | 1 μg/m³ |

| Work temperature: | -10 °C to 60 °C (Outdoor) |

| Humidity (work): | 0-99% |

| Size: | 50 x 38 x 21 mm |

| Shipment Weight | 0.040 kg |

| Shipment Dimensions | 7 × 5 × 3 cm |

Please allow 5% measuring deviation due to manual measurement.

RoboticsBD RoboticsBD RoboticsBD RoboticsBD RoboticsBD RoboticsBD RoboticsBD RoboticsBD RoboticsBD RoboticsBD

1 x PM2.5 Air Quality Sensor PMS5003 High Precision Digital Output Module.

RoboticsBD RoboticsBD RoboticsBD RoboticsBD RoboticsBD RoboticsBD RoboticsBD RoboticsBD RoboticsBD RoboticsBD

RoboticsBD RoboticsBD RoboticsBD RoboticsBD RoboticsBD RoboticsBD RoboticsBD RoboticsBD RoboticsBD RoboticsBD

The latest price of PM2.5 Air Quality Sensor PMS5003 High Precision Digital Output Module in Bangladesh is BDT 2,990 You can buy the PM2.5 Air Quality Sensor PMS5003 High Precision Digital Output Module at best price from our RoboticsBD or visit RoboticsBD Office.

|

Please note that the product information provided on our website may not be entirely accurate as it is collected from various sources on the web. While we strive to provide the most up-to-date information possible, we cannot guarantee its accuracy. We recommend that you always read the product labels, warnings, and directions before using any product. |

|

Product Images are shown for illustrative purposes only and may differ from the actual product. |

Need to be careful about the circuit connection as it should be compatible to the code. I've tried it to connect with arduino uno and nodemcu 8266 and was successful. To connect to arduino mega or other mcu code should be modified accordingly. Result is most probably close to accurate so it can be taken as a standatd for manually calculating particulate matter.

Reference: RBD-0009

54 Digital I/O terminals (14 of which have programmable PWM outputs). 16 Analog Inputs. 4 UARTs (hardware serial ports). 16 MHz crystal clock. RoboticsBD Operating voltage: 6 ~ 12v. Dimensions: 110 x 53 x 15 mm.

Reference: RBD-0094

The Arduino Uno R3 High-Quality Edition Arduino UNO in Bangladesh Micro-controller : ATmega328. Operating Voltage : 5V. Input Voltage (recommended) : 7-12V. Digital I/O Pins : 14 (of which 6 provide PWM output). Analog Input Pins : 6. The Arduino Uno R3 High-Quality Edition embodies superior craftsmanship and meticulous attention to detail, resulting in...

Reference: RBD-0323

Microcontroller ATmega328 (SMD) – Interface CH340G Operating Voltage: 5V Input Voltage (recommended): 7-12V Digital I / O Pins 14 (of which 6 provide PWM output) RoboticsBD Analog Input Pins: 6 A programming cable is included.

Reference: RBD-0958

Five Operating Modes Integrated MCU Onboard Processing Standard I2C Digital Interface Optimized Low-Power Modes Optional NTC Thermistor Pins

Reference: RBD-1654

5 In 1 Portable CO2 Detector Air Quality Detector Intelligent Air Detector Temperature and Humidity Sensor Carbon Dioxide Monitor TVOC Formaldehyde Detection HCHO Detector Color Black

Reference: RBD-1716

Working Voltage: 5.0V Maximum Working Current: 100mA Data Interface Level: L<0.8V, H>2.7V, maximum voltage level 3.3V Particle Measurement Range: 0.3 ~ 1.0μm; 1.0 ~ 2.5μm; 2.5 ~ 10μm Note: Please purchase this adapter board to use it with Arduino and Raspberry Pi.

Reference: RBD-1717

Wide voltage operation: 3.3~5.5V 0~2.3V analog signal output, compatible with 5V, 3.3V two control systems The excitation source is an AC signal, effectively preventing probe polarization Waterproof probe for long-term immersion in water

Reference: RBD-1751

Detection Gas: H2, Alcohol, CO, VOC Detection Range: 10~500ppmH2 5~500ppm Alcohol 10~500ppm CO Air Quality Sensor Module

Reference: RBD-0142

Description: Fingerprint scanners are awesome. Why use a key when you have one right at the tip of your finger? Unfortunately, they’re usually unreliable or difficult to implement. Well not anymore! We’ve found this great fingerprint module from ADH-Tech that communicates over TTL Serial so you can easily embed it into your next project.

Reference: RBD-0291

Main chip: LM393, Electret condenser microphone Working voltage: DC 3.3-5V Induction distance is 0.5M Signal output Indication Single channel signal output The output effective signal is low level.

Reference: RBD-1424

Onboard precision microcurrent transformer. Onboard sampling resistor. The module can measure AC currents less than 5A, the corresponding analog output 5A/5mA. Rated input current: 5A Rated output current: 5mA Change: 1000: 1 The linear range: 0 ~ 10A (100 ohms) Linearity: 0.2%

Reference: RBD-0523

Module Power: 5.00V Module Size : 43 x 32mm(1.69×1.26″) Measuring Range :0 – 14PH Measuring Temperature: 0 – 60 ℃ Accuracy : ± 0.1pH (25 ℃)

Reference: RBD-0668

Crystal 32.768KHz, matching capacitance 6pF DS1302 8-pin SMD homemade chips Seconds, Minutes, Hours, Day of Month, Day of Week, and Year Operating temperature: 0 degree — 70 degree. RoboticsBD

Reference: RBD-1860

Model KS-RG22 Coaxial reflection type Supply voltage DC10-30V±10%

Reference: RBD-0679

Sensitivity to Ammonia, Sulfide and Benzene steam Sensitive for benzene, alcohol, smoke Fast response and recovery Adjustable sensitivity. RoboticsBD Signal output indicator Output voltage boosts along with the concentration of the measured gases increases.

Reference: RBD-1200

Very low supply current Photo-detector and preamplifier in one package Internal filter for PCM frequency Improved shielding against EMI Supply voltage: 2.5 V to 5.5 V Improved immunity against ambient light

Reference: RBD-1193

Infrared Photodiode Transmitter 3mm Infrared Photodiode Receiver 3mm

Reference: RBD-1191

Internal filter for PCM frequency. Inner shield, good anti-interference ability. High immunity against ambient light. Improved shielding against electric field disturbance 3.0V or 5.0V supply voltage; low power consumption. TTL and CMOS compatibility. Suitable transmission code:NEC code,RC5 code. Universal receiver. 38 KHz. Infrared remote control receiver.

Reference: RBD-2099

Main chip: LM393 Working voltage: for DC 5V Single-channel signal output Low-level output signal used for human body touch sensor alarm Adjustable sensitivity Pin Connector to board: 4 Pins

Reference: RBD-0688

Wide input supply (2.5 V to 12V) Easy to integrate (V+, GND, and Data) The device in deep sleep mode when Data pin is grounded Very small dimension.

Reference: RBD-0414

A probe by new original installation import DS18B20 temperature sensor chip. RoboticsBD Chip each pin use heat shrinkable tube to prevent short circuit, internal sealing glue, waterproof, moistureproof. Stainless steel tube encapsulation waterproof moistureproof prevent rust. Stainless steel shell (6 * 45 mm), lead length 100 cm (shielding wire) use...

Reference: RBD-2079

This is 38KHz Infrared IR transmitter sensor module For Arduino Transmit 38KHz modulating signal Suitable for Arduino DIY project Material: PCB

Reference: RBD-2075

MQ-2 Smoke Gas Detector Sensor ME084 Module for Arduino Operating Voltage:+5V Preheat Duration:20 s

Reference: RBD-2172

Easily customizable to a wide range of sizes Cost-effective Ultra-thin; 0.45 mm Robust; up to 10 million actuations Simple and easy to Integrate. RoboticsBD Force Sensitive Resistor Square High Quality

Reference: RBD-0145

Dual output mode, analog output more accurate A fixed bolt hole for easy installation With power indicator (red) and digital switching output indicator (green) Having LM393 comparator chip, stable. Operating Voltage: 3.3V~5V

Reference: RBD-0156

Operating Voltage: 3V-5V High-resolution conversion of light intensity to frequency. Chip pins all has drawn for standard 100. Put the needle (2.54 mm). Mil-convenient for bitmap board. Programmable color and full-scale output frequency. Communicate directly with a microcontroller. Low-profile surface mount package.

Reference: RBD-0423

Detecting range: >120 degree Analog and digital outputs On-board potentiometer and indicators 1% resistors to make this module more reliable and precise Operating Voltage: 3.3V – 9V Board Diameter: 40 mm.

Reference: RBD-0152

Using SW-420 normally closed type vibration sensor Comparator output, clean signal, good waveform, strong driving ability, >15mA Operating voltage 3.3V ~ 5V Output format: digital switching output (0 and 1) Using a wide voltage LM393 comparator With bolt holes for easy installation

Reference: RBD-0441

Power supply voltage: DC5 ± 2V Sensitivity: 0.5V / (0.1mg / m3) The minimum detection level of particles: 0.8 m Clean air voltage: 0.9V typ. Low consumption current (Icc: MAX. 20 mA) The presence of dust can be detected by the photometry of only one pulse Enable to distinguish smoke from house dust RoboticsBD

Reference: RBD-0358

Dimensions: 11×15 x 2 (L x W x H) mm Weight: 1gm Mutual transform between 5V TTL and 3.3V TTL Two channels of logic and high voltage low voltage logic can two-way transform Portable and lightness, with 2 rows 4 pin contact pins

Reference: RBD-2152

Human Presence Radar LD2410 Respiration and Heartbeat Monitoring Non-contact Induction Sensor High-sensitivity 24GHz sensing module

Reference: RBD-1946

Comes with the BME280 sensor. Pressure accuracy of ±1 hPa. Temperature accuracy ±1.0°C. Altimeter accuracy ±1 meter. Humidity: +-3%

Reference: RBD-2214

EMG muscle sensor V3.0 with cable and electrodes Measures the electrical activity of muscles High signal quality for accurate and reliable measurement Adjustable gain and filtering for signal conditioning Compatible with various types of microcontrollers and data acquisition systems Comes with reusable electrodes and a 3.5mm jack cable for easy connection

Reference: RBD-1836

Input Current : 0-30A Output Mode: 0-1V @ 30mA Frequency: 50HZ-150KHZ Opening Size: 13 x 13mm/ 0.5″ x 0.5″(L*W) Output Plug 3.5mm Dielectric Strength 6000V AC/1min Suitable for lighting equipment, AC motors, air compressors, monitoring, current measurement, and protection Meet UL94-V0 flame retardant properties

Reference: RBD-2146

Operating voltage:3.3V/5V Sensitivity: Adjustable via a potentiometer Input Signal: Resistance, NOT Conductivity Output Signal: Voltage, analog reading Finger contact material: Nickel

Reference: RBD-1757

Supply Voltage: 3.3 V/ 5V. Interface Type: I²C, SPI. Sensing Range: ±2g, ±4g, ±8g, ±16g. Sensitivity: X: 28.6 LSB/g. Y: 31.2 LSB/g. Z: 34.5 LSB/g. Ultra Low Power: 40µA in measurement mode, 0.1µA in standby@ 2.5V. Free-Fall Detection. Tap/Double Tap Detection.

Reference: RBD-1727

This is 38KHz Infrared IR transmitter sensor module For Arduino Transmit 38KHz modulating signal Suitable for Arduino DIY project Material: PCB

Reference: RBD-1423

Sony IMX477R stacked, back-illuminated sensor. Resolution: 12.3 megapixels. Compatible with Raspberry Pi 1/2/3/4 boards Output: RAW12/10/8, COMP8 Back focus: Adjustable (12.5 mm–22.4 mm) Lens standards: C-mount, CS-mount (C-CS adapter included) IR cut filter: Integrated Wide Field of View suitable for CCTV applications Suitable for macro photography...

Reference: RBD-0923

Measuring range: temperature -40-80 ℃; humidity 0; 99.9%RH Measurement accuracy (25℃): temperature: + 0.5; humidity: + 2%RH (10; 90%RH) Resolution: temperature: 0.1 ℃, humidity: 0.1%RH Attenuation value: temperature: <1℃ / year; humidity: < 1%RH/ years High precision Capacitive type Full range temperature compensated Relative humidity and...

Reference: 1730

Through-hole design. Shaft Shape: Round Base Size (mm): 6mm and 7mm Middle stroke 1.05mm and 2mm Shaft Size: 10 different Size (find the details in Package Includes section below) Please Choose Size Below:

Reference: RBD-0948

Built-in Flash: 32Mbit Power supply: 5V WiFi protocol: IEEE 802.11 b/g/n Peripheral interface: UART/GPIO/ADC/DAC/SDIO/PWM/I2C/I2S Logic level: 3.3V A high-quality USB cable is essential for this board to ensure sufficient current supply; otherwise, your board may not be recognized by the Windows Device Manager. Please avoid using mobile phone cables and...

Reference: RBD-1875

Fully compatible with the PC. Moulded strain relief and PVC over moulding to ensure a lifetime of error-free data transmissions. Aluminium under mould shield helps meet FCC requirements on KMI/RFI interference. Foil and braid shield complies with fully rated cable specifications reducing EMI/FRI interference.

Reference: RBD-2268

Features WiFi+Bluetooth connectivity with the ESP-WROOM-32 module Accessible I/O pins via extension headers for easy customization Onboard USB CH340 for convenient programming and debugging 2x keys for reset or user-defined functions ESP32S-DEV development board is a cost-effective solution for a wide range of applications.A high-quality USB cable is...

Reference: RBD-0673

Detecting range: 300~10000ppm Signal output indicator. Dual Signal output (analog output and TTL output). The TTL output signal is low level, allows us to connect with SCM directly. Analog output 0~5V voltage. Quick response and recovery. RoboticsBD

Reference: RBD-2106

40P color jumper wires Length: 300mm Weight: 45 gm Compatible with 2.54mm spacing pin headers High quality and in good working condition Durable and reusable Easy to install and use

Reference: RBD-0353

Driver IC: SSD1306 Support wide voltage: 3.3V-5V DC Communication: IIC Working temperature: -30-80 degrees. RoboticsBD